It begins with the harvest, with picking the fruits at the right point of ripeness and flavor. To do this, the COMARK juice filling line are laundered to rid them of soil and tiny bugs. From there the fruit is put through machines that squeeze out the juice.

When producing juice it is just important to ensure your juice tastes good and safe in the process, this is very crucial especially if you making a mass bottling lines juice for wholesales. At COMARK, we take many quality control measures to give you the best juice possible.

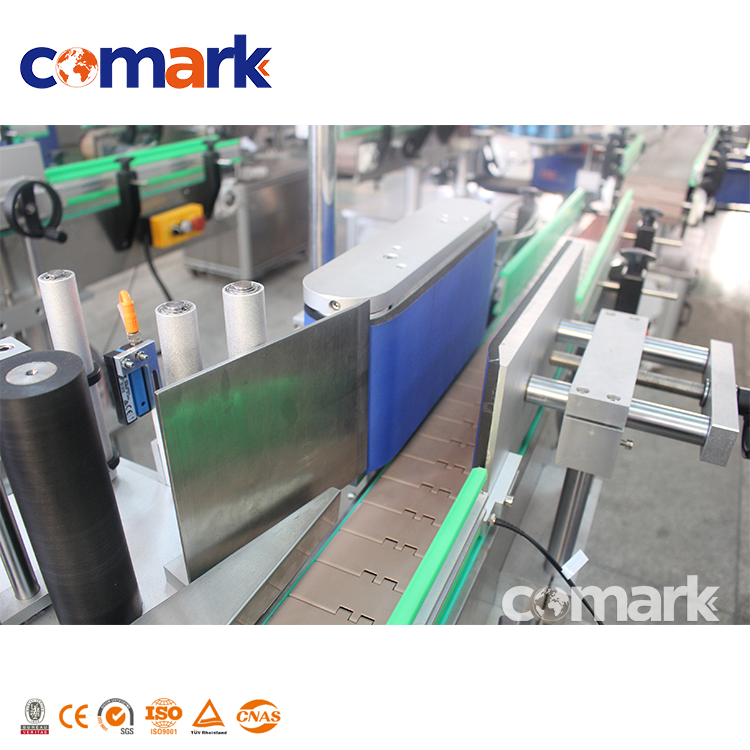

As the juice-making process proceeds, we sample the juice regularly for things like color, taste and smell. This COMARK juice packaging line helps us ensure that the juice tastes fresh and looks good. We taste the juice as well to determine the correct level of sugar and acidity.

What’s more, the equipment you use in this juice factory is carefully cleaned before and after it processes your juice. This juices bottling line can help prevent the spread of germs. We taste the juice as well to determine the correct level of sugar and acidity. Workers also don clean clothes and follow rigorous hygiene practices to ensure that everything remains safe. Through these QC procedures, guarantees that every bottle of juice is healthy, delicious and fresh for customers who purchase in bulk.

We know what those typical problems are and how to prevent them so that you can always get the highest quality juice. What’s more, the equipment you use in this juice factory is carefully cleaned before and after it processes your juice. This juice making machine is a way in which the little germs or dirty things can get into the juice, making it unsafe or causing it to spoil quickly.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.