Labeling machines do a great job putting a label on any item quickly and accurately. The machines are in use across a wide range of industries, including food, drinks, medicines and cosmetics. Rather than having people slap labels on manually, these machines worked faster and with fewer mistakes. They don’t get tired working all day, which allows companies to handle large orders. Automated labeling machines also provide neat and professional product finishes. COMARK manufactures tough and simple machines. And while factories use COMARK’s machines and save time and money, customers get well-labeled products every time.

It can be challenging to find good high volume automated labeling machines for sale. There are a lot of machines for sale but not all are as well made or last as long. The Details COMARK has been in the business for decades, building machines that can take a licking and keep on ticking. If you want to buy many labeling machines in bulk, you should find a supplier who knows what you are looking for. COMARK provides machines for various product dimensions and types, which means that you will definitely find the solution that suits your factory’s work. Purchasing wholesale from COMARK means you’ll receive machines that aren’t only supported but also come with training. Companies selling inexpensive machines that brerak after a couple of months lose out in the long run. COMARK tests its machines for quality before shipping them, so you won’t run into those issues. COMARK also collaborates closely with customers to assist them in selecting the appropriate machine, whether it’s for large or small orders. If you demand machines that won’t let your operation down, it makes sense to search for reputable sellers such as COMARK! And purchasing multiple units can lead to better prices and speedier delivery. The last thing you want to do is spend time repairing machines or waiting for parts, so you need machines you can trust from a source with a good reputation. COMARK’s own employees walk you through all of that, making sure what you buy is what your need and can afford. You will have confidence that you are taking no risk with wholesale purchases from COMARK to obtain excellent machines in time.

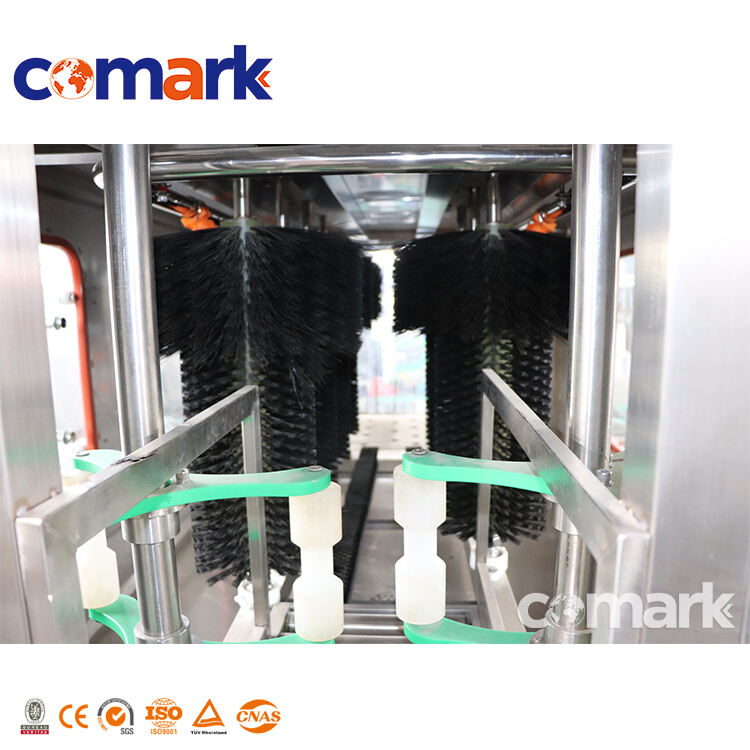

When it comes to selecting the perfect automated labeling machine, many factors come into play. All machines from COMARK include a range of useful parts to help with fast, easy labeling. First, the machine must take care of various label sizes and shapes. Some products ask for small labels; others, large ones — so flexibility matters as well. Second, speed matters. A decent machine can label a whole lot of products in a minute without so much as blinking. COMARK’s machines offer fast motors and smart controls to meet the pace of busy production lines. Third, the machine should be straightforward to use. If it’s complex, workers might make mistakes or require additional training. COMARK’s machines are designed to have simple buttons and clear screens so anyone can learn them fast. Fourth, it should be strong and durable. COMARK “specifies materials that are robust so the machines don’t fail despite being worked hard day in, day out. A further option is the possibility to reposition labelling. “Every now and then, labels have to land just so in one place, and COMARK’s machines allow you to adjust label placers without even shutting the machine down. Safety is also important. Decent machines have guards and sensors to keep workers safe while they label. Safety Features: COMARK care about safety features so accidents don’t happen. Finally, and this is very important: easy upkeep. Machines require periodic cleaning and minor repairs. COMARK builds their machines so components can be swapped out rapidly, incurring less downtime. When you are in need of automated labelers, consider how that machine will fit into your factory. COMARK’s equipment is designed to accommodate a variety of applications, ensuring your labeling operation runs smoothly day in and day out.

If you have a large business and it is necessary to place labels on your products every day, choosing the best automatic labeling machine carefully will become of utmost importance. An automatic labeling machine makes it easy to put labels on bottles, boxes, cans, and other products neatly and quickly. He said it saves time and ensures that each product will look good. But which is the best one to use when it comes time for large-scale projects? The first thing is to decide how much speed you require. If your business is a high-volume seller of items, you’ll want a machine that can keep going without pausing to catch its breath. COMARK have machines that work quickly and efficiently so you won’t be sat at the label for ages! Next, consider the machine’s size and design. And it ought to be a good fit in your space, easy to use. COMARK machines are meant to be easy enough for workers to quickly learn how to use them — and not make mistakes. Another significant consideration is the kind of labels that the machine can work with. Other machines are only compatible with specific shaped or sized labels, but when it comes to COMARK machines they can find a variety of uses for different sizes, shapes and types of labels. This means that you can label a wide variety of products without having to purchase new machines. Also look at how easy or complex it is to clean and repair the machine. When big operations are running right, machines should be reliable and easy to keep ticking. “COMARK produces strong machines that are easy to maintain and if something does go wrong then they find me the replacement part quick and I can keep on working.” Finally, think about your budget. Big machines can be expensive, but you don’t want to get a machine that, in the long run, makes it harder for you to save by not working well and breaking down. COMARK provide excellent machines at a cost-quality that is successful work the other way for you. In summary, when it comes to selecting an automatic labeling process for a high-volume manufacturer, consider speed, size and label type in addition to ease of use, maintenance and price. COMARK is a the perfect fit as their machines meet all of these needs, and keeps your business humming.

That’s where automated labelers come in useful, but they too can run into issues. When you understand common problems and how to address them, you can save time and keep your business running. One frequent issue is that labels don’t adhere well to the products. This may occur if label or product is soiled with dirt or moisture. To correct this problem, ensure that both product surface and label are clean and dry before apply label. The COMARK machines usually have built in checks to assist with this but cleanliness is always crucial. Another problem is that labels may get wrinkled or ripped during the practice. This is generally due to an excessive speed setting on the machine or if the label roll was not loaded correctly. This problem can be eliminated by crest-slowing the machine and reloaded the label roll gently. COMARK’s machines are built for quick loading of labels, and limit errors. Occasionally, the machine will malfunction or jam. This can happen if parts are dirty or there is a mechanical issue. It is wise to periodically run a check on the machine, clean moving parts and look for worn material. COMARK provides simple instructions and support to ensure your machine continues running well. Labels may be placed wrong as well, which means they are either not straight or in the wrong position. If the machine has not been incorrectly set-up, this can occur. This is fixed by you taking the time to adjust settings and test your machine on a few products before starting. COMARK equipment has easy controls that are easy to adjust for operators. Finally, freezing or strange behaviour can result from electrical or software problems. However, these issues can often be solved by either restarting the machine or updating its software. If you need technical assistance, COMARK's customer service is ready to assist. Knowing these common issues and how to fix them will keep your automatic labeling machine running well. With COMARK hardware and support, smarter troubleshooting makes it easy to scale your operation.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.