The process involved in preparation of juice is a large undertaking that involves a number of machines. Once fruits or vegetables in large amounts are turned into juice, it is done step by step using a special set of machine. There it has been referred to as juices bottling line. It accomplishes it more swiftly, neatly and in larger amounts than I might ever have imagined. The juice is washed, crushed, pressed, filtered and packed in just one flow by the machines. These juices are bottling line by our company, COMARK and we make them to operate smoothly and long. Juice processing lines are relevant to most companies who want to have a fresh beverage but they do not want to consume your time and money.

The process of selecting the appropriate juice processing line is not easy since there are numerous options and factors that you must consider. Among them is the size of the line. Big manufacturers require machinery that could produce thousands of liters each day, whereas smaller could do with more. The lines that COMARK offers can be tailored to suit many different requirements and the choice of the right size does not require one to spend money on something that is either too large or too small.

Increasing numbers of juice lines are becoming high-tech and using computers to do all that. These computers also give access to the internet and the workers can watch the juice-making process using a remote location. In case something is wrong, they are notified by their phone and able to fix it in a short time. All this newfangled technology is facilitating the juice processing process easier, faster and as it were better than ever. We are pleased to give everyone delicious and also safe juice by offering these smart and environmentally friendly solutions of juice filling line to the juice makers.

The Discussion on the use of Juice Processing Lines to provide high-quality juices in bulk orders. Juice can be requested as a liquid extract that is naturally made out of fruits and vegetables.

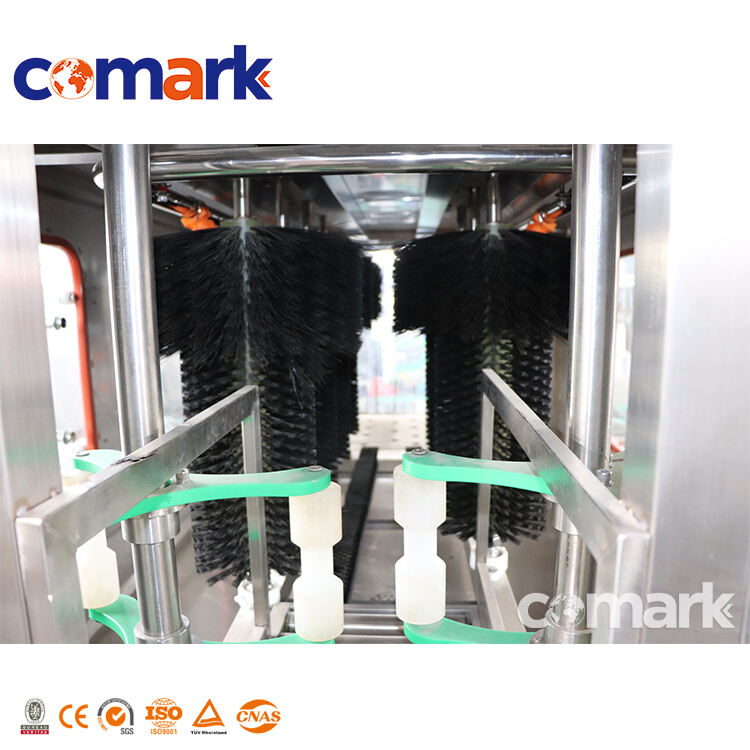

In case businesses buy juice in large quantities, they anticipate that the juice should be safe and good to drink. COMARK juice processing line also helps in providing same high standard of all juices bottles. The machines are used to clean the produce very well before commencing. It cleanses it of dirt and germs and barks. This is followed by the juice preparation using special press and filters which squeeze out the tastiest juice without adding anything that contributes to a nasty flavor such as pesticides. The juice filling machine of COMARK Juice Filling Machine also keep the juice at the right temperature during the process. The juice may lose taste or spoil easily in case of excessive temperatures whether hot or cold.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.