Soda bottling machines in glass bottles are very crucial for soda manufacturing has to do. These machines help to quickly and carefully get soda into glass bottles. That process needs to be done cleanly so the soda remains fresh and safe to drink. Soda companies, though, when they have good filling machines, can make many bottles in a short amount of time without spilling any or wasting soda. COMARK produces soda bottling plant machine that do this particular job very well.

There are some common problems in the use of glass bottle soda filling machine: These are great in terms of speed-filling soda and maintaining its freshness early in the day. But in some cases, things can go awry. One of the most frequently encountered is bottles breaking during fill. Glass is delicate and if the machine isn’t calibrated accurately, bottles can strike hard parts or travel too rapidly, leading to cracks or breaks. To remedy this, adjust the machine’s speed so that it is not at a high setting and confirm you have set your bottle holders close enough for the bottles to be held gently but with some force.

And that’s not to mention the soda spilling and leaking from the bottles. This can occur when the filling nozzles are not clean or when the machine’s filling level is improperly maintained. When soda spills, it’s a complete waste and the area becomes sticky and hazardous to work in. To alleviate this, simply keep the nozzles clean and drop the COMARK soda water filling machine settings down to fill bottles just enough so they aren’t overflowing.

At times for small technical issues or power connections the machine may suddenly stop working. This can stall the entire production line. The only way to fix it is by regularly checking all of the electrical components and by maintaining a regulated power supply. And a knowledgeable operator who is adept at getting the machine re-set in short order can also help minimize downtime.

It is very important to keep the glass bottle soda filling machines in good condition, when a manufacturer fills soda bottles in bulk. Vigilant upkeep helps those machines to run well for a long time without the need for costly repairs or slowdowns. We would love to help soda producers understand exactly how they can maintain these COMARK soda bottling machine, and make them always run as well as they should.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

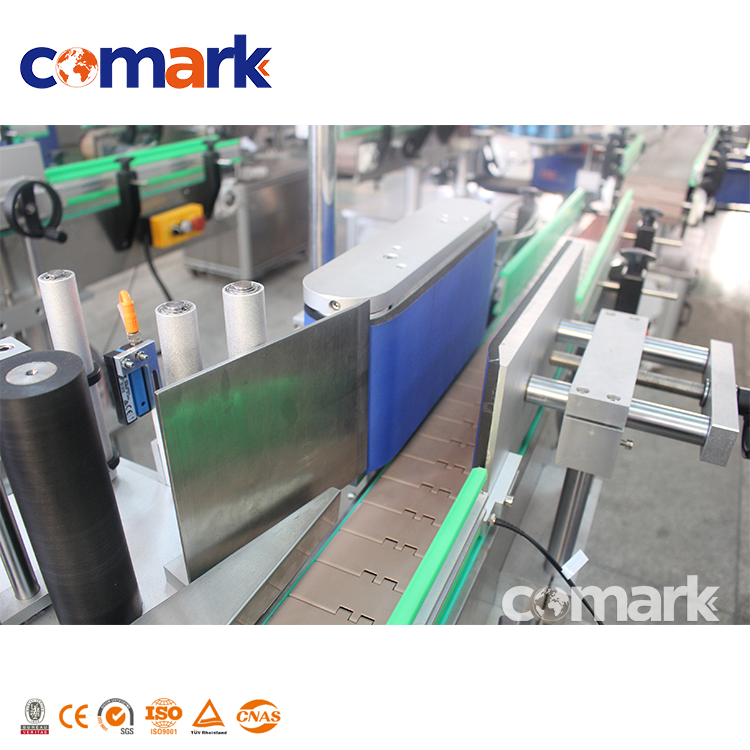

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.