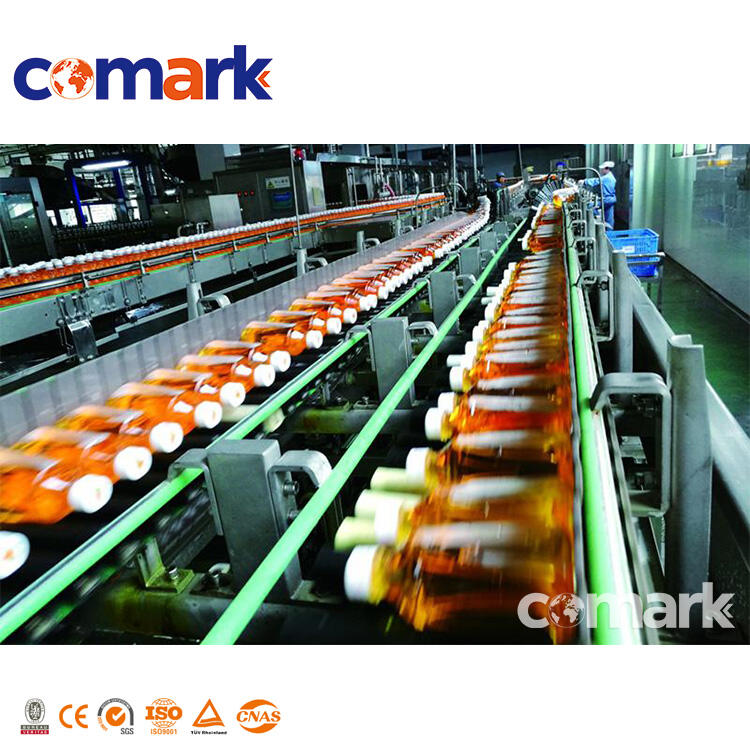

Fruit juice filling machines are one of the main essentials when a brand decides to produce juice bottles in a faster and more sanitized way. These machines make the process of getting the juice into the bottle in such a way that the time is saved and the juice remains fresh. If you think about the number of bottles of juice that are being sold every day in the stores, it is unbelievable how fast and accurate machines like COMARK ones work to finish the task. Filling juice by hand, without these machines, is a lot slower and there is a chance that the juice may spill or become contaminated. The juice is very precise and no bottles are filled with extra. Some machines can handle multiple types and sizes of bottles that make them very suitable for juice factories where numerous kinds of juices are sold. COMARK juice filling line machines are not only strong but also simple in design and great for your workers to use as they make their job easier.

Operating fruit juice filling machines seems to be a simple task but there can still be problems related to it. The agents that can be one of such problems is the machine’s nozzles getting clogged. The juice can be one of the pulpy and pieces of pulp or fruit get caught and clog the juice from coming out in a way that is proper. When this happens, the fruit juice making machine can begin to fill slowly bottles, or stop working completely. To do this, keeping nozzles clean is very important. A filter placed just before the juice going into the machine can also be helpful in preventing clogs

By operating these parts and controlling them you can be sure of your filling accuracy constantly. Sometimes the machine can leak juice that is a wasteful and messy thing. Leakages usually take place at seals or gaskets that have been worn out. The exchange of these components can help you to avoid leaks if it is done in due time. Furthermore, if the machine is shaking a lot and making strange noises, it could be that some screws are loose or that parts need lubricating. You are only COMARK'S tips away from the machine's well-being. Being aware of tiny matters is a way to refrain from catastrophic breakdowns which in turn saves your time and money.

Good juice to a large extent is a result of good thinking which not only goes beyond the juicing part but also to bottling. Filling machines used for fruit juice by COMARK are a very significant part of this legacy. These devices transfer the liquid into bottles in a sterile environment that does not allow germs to come in contact with the juice. Apart from that, the machines also perform the work very fast, thus, the juice is not left to stand for a long time and lose its taste or vitamins

There are some machines that can even perform the work without allowing air to enter the bottle - this is good for keeping oxygen away from your juice, which is the main cause of oxidation. Oxidation can also alter the color as well as the flavor - not very good for juice. Thus, a filling machine can be instrumental in keeping the natural color as well as the fresh flavor of the juice for a longer period of time.

When companies produce and package juice, it is necessary to have a tool that can accomplish the task of filling in a fast and efficient manner. These machines do the job of filling bottles or other containers with juice by a quick and accurate method that can be trusted. Till the time these machines came into use, people used to fill the bottles by hand — a process that not only took a considerable amount of time but was also prone to mistakes such as spilling, overfilling or under-filling. But with COMARK’s juice making machine, they make it easier and quicker. The device is capable of filling a large number of bottles within a few minutes; thus, it is much faster than manual work

That's more juice that can be packaged and sold, in turn, allowing the businesses to enlarge their operations and at the same time, keep the customers satisfied. The machines also save fruit juice in another way by making sure it stays clean and safe. The filling part is done inside the machine, thus it lessens the risk of contamination by germs or dirt. It is very important to ensure that the juice stays fresh for consumers to drink, he commented.

There are numerous fruit juice filling machine options available, so you can determine the best value according to your requirements and budget if you want to fill multiple bottles at once. COMARK, on its part, can offer a better price when selling products in bulk (including custom options) like computer servers because the company can negotiate discounts with manufacturers. So, in essence, if you need more than one machine for your business, buying from COMARK can be a way of saving money

You should be searching for a company that has not only low prices but also good customer service. COMARK helps by answering questions and giving guidance as to which machine will be the most suitable for your juice or beverage packaging needs. The availability of this kind of support makes it easier to choose the right machine and thereby lessen the chances of making mistakes.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.