Water Bottling Equipment will be essential for businesses that require the machine to produce their own bottled water. It speeds the process of filling bottles, so customers can get an urgent drink expediently. Firms such as COMARK offer a variety of machines that can assist with this. A company can make high-quality bottled water with the right equipment. It’s not just filling bottles, though; equipment for cleaning and labeling and packaging comes with it. The right equipment can make or break any water bottling business. For example, using an Automatic Rotary OPP Hot Melt Glue Labeling Machine can enhance your labeling process significantly.

If you are in the market for premium bottling water equipment for your business, then there are a few items that you should be considering. Firstly, you have to look at the materials, which is used in these machines. Stainless steel works well because it is strong and can be rust-resistant. You also want to ensure that the equipment is straightforward to clean. Clean machinery is an important part of keeping the water safe. Next, consider the dimensions of your equipment. If you want to sell a large volume of water, you need machines that can keep up with your production requirements. Different Businesses sizes COMARK – You will find equipments of different sizes since your business cannot fit into only one size. You also want to consider machines that are "user-friendly." Some machines can require specialized training to operate. But the easier they are to operate, the quicker your workers can fill bottles. Also, look at the machines' energy ratings. Less energy-consuming equipment can provide long-term savings. Finally, consider checking reviews or contacting other businesses who can speak to their experience with the equipment. This might clue you in on what to look for when it comes to bottling water. You might want to explore options like the 5 Gallon Automatic 600BPH Water Bottle Filling Machine Plant to meet your production needs.

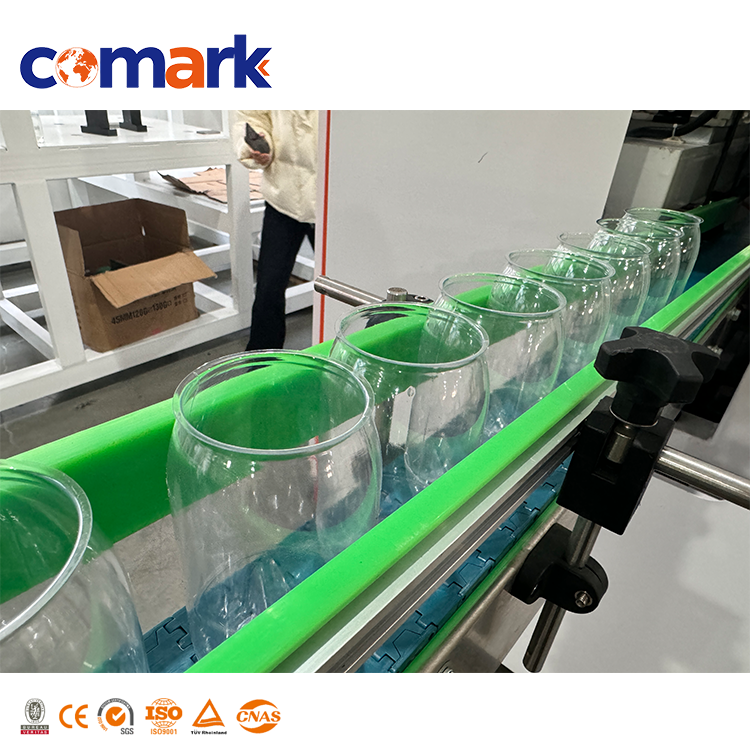

Bottling water machinery can really transform the way that your business operates. When you have the correct machines, you can bottle things more quickly. This allows you to serve more customers in less time. If, say, a machine can fill 500 bottles in an hour — and your old machine could only do 200 — you’re losing a lot of opportunity and time. Faster machines translate into less waiting time for customers. Another way that equipment helps is by minimizing errors. When properly calibrated, machines can fill bottles with the correct amount of water every time. That keeps customers satisfied and reduces waste. COMARK products are also equipped with additional elements for monitoring the filling process, as well as functionality to make sure everything is running properly. That can help you rest easier. Plus, the automated labeling and packaging saves you even more time and effort. A good production line will never fail to get you off the ground. Good bottling water equipment, therefore, is a wise investment for any business looking to expand.

Finding the best wholesale bottling water equipment suppliers can be difficult when you don't know where to start. Trusted suppliers can be found in a number of places, and one of the best is online. Thousands of water bottling equipment is being sold by various companies on industrial equipment websites. You can look up "bottling water equipment suppliers" to see what you come across. You can also research which suppliers are reliable by reading customer reviews. Yet another great way to source suppliers is by visiting trade shows. In these shows many companies exhibit products; among them bottling water equipment is also displayed. You can speak to the people who develop the machines, and ask anything you like.” It’s a great opportunity to learn more about the gear you might consider buying. Local directories of businesses are also useful. They typically have a list of suppliers in your area, which may allow you to visit them in person. COMARK is a trusted name in quality bottling water equipment. They have a range of various machines you can use to get into the water business or expand an existing one. And be sure to shop around for price and services from different suppliers. Some might have better terms or more rewarding support than others. Make sure you discuss warranties and after-sale services for a great investment. A lot can hinge on who you choose as a supplier so take your time and shop around.

Common Problems Using Bottling Water Equipment If you are using bottling water equipment, there will be some common problems that can happen. Among the most common is the fact that they can jam. That can occur if the bottles are not in the right position, or if there is a problem with the machine itself. When a jam happens, it has the potential of slowing down operations and delaying production. This is something that can be avoided through the use of regular maintenance. Another issue that may occur is leaks. If the bottling line leaks, there may be water waste. It can also be unsafe for workers. Implementing a good maintenance programme and using of durable materials reduces the extent of this issue. Equipment breakdowns can also occur. On some occasions, parts of the machines wear down or stop working, shutting production down altogether. It’s useful to have spare parts and do preventive checks to make everything run smoothly. Also, on occasion the bottling machine can print or align labels incorrectly on the bottle. This will confuse users, and make your product seem unprofessional. The equipment being developed by COMARK is explicitly intended to minimize these problems, but knowledge of the problem space can make you better prepared. Providing training for your employees in using these machines correctly can also minimize the risk of problems. By paying close attention to your gear and dealing with problems early, you'll maintain high efficiency for the process of bottling.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.