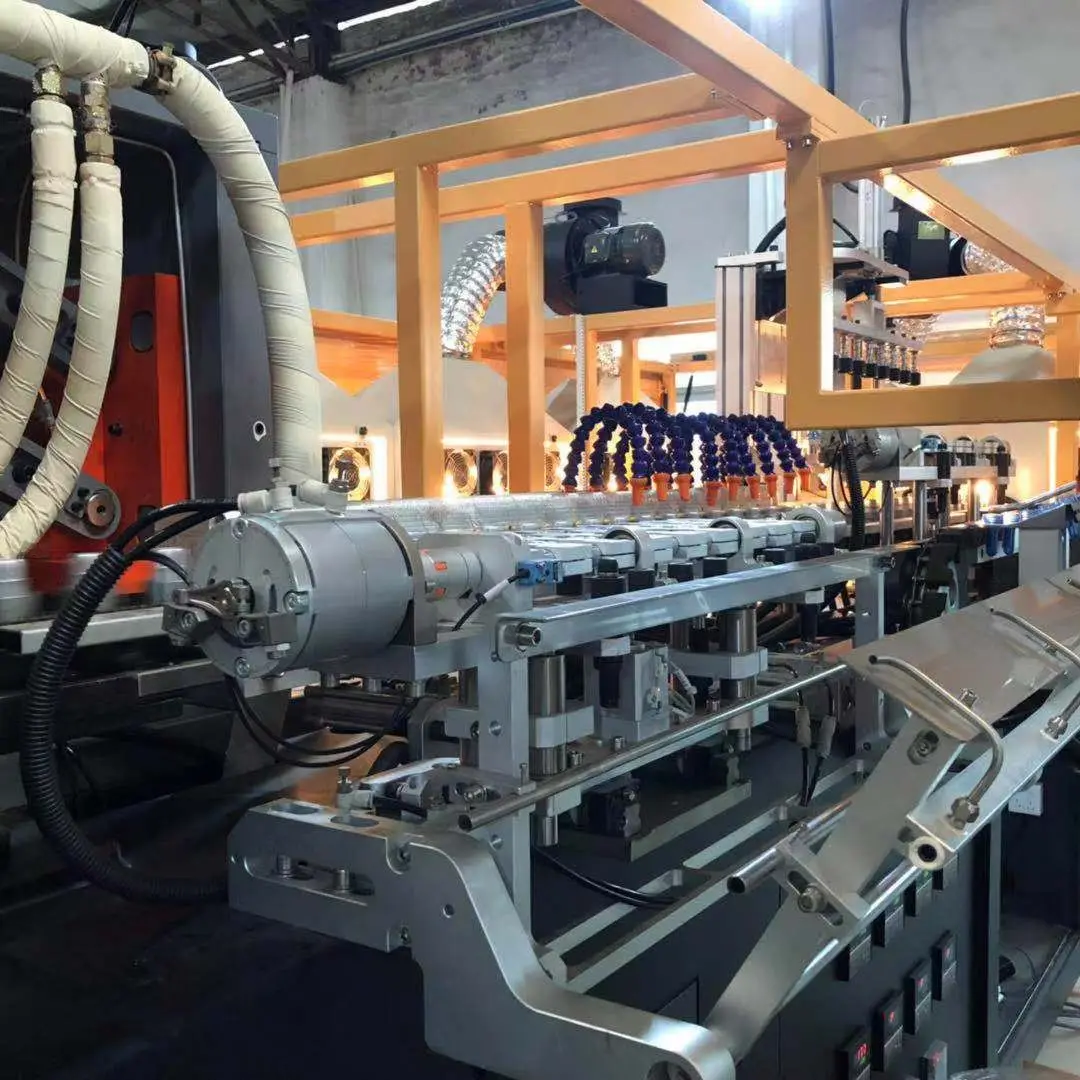

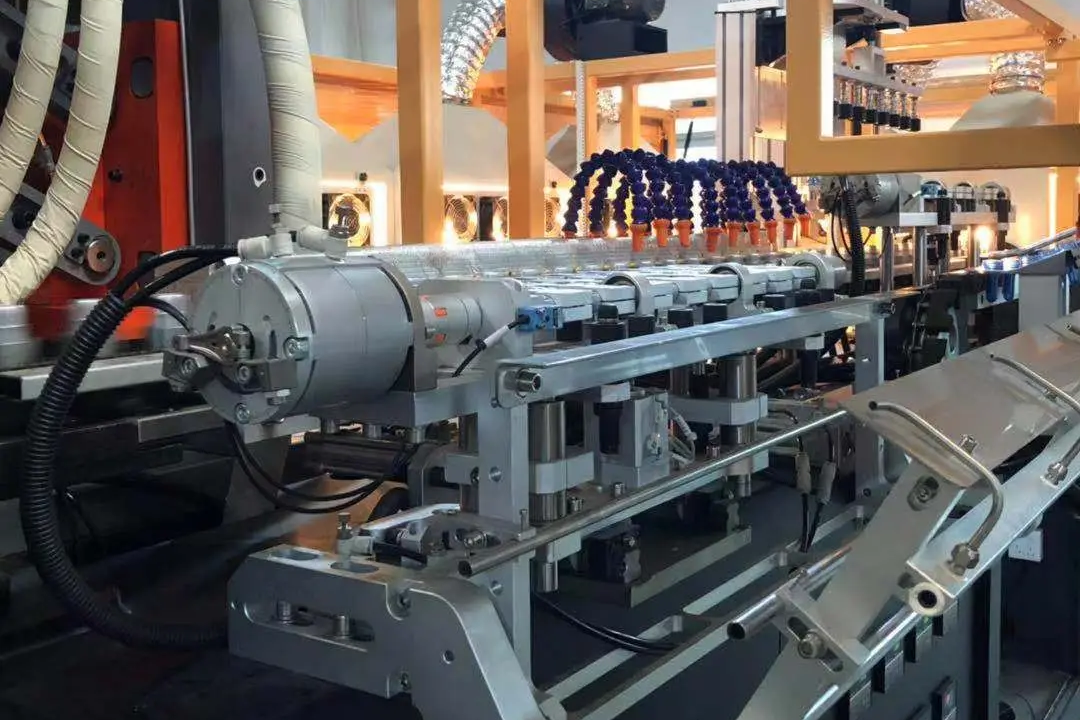

Plastik mahsulot ishlab chiqarishni oson va qadrlantirish uchun kompaktlik va davomiylik talab etiladi, va bu xizmatlarni COMARK Blow Moulding Mashinasi taqdim etadi. U eng so'nggi texnologiyalardan foydalanadi, shuning uchun plastik mahsulotlarni sifatli va muvofiqlikda ishlab chiqarish imkoniyatiga ega bo'ladi. U yana berilgan xususiyatlarga malik bo'lib, ishlab chiqarish jarayonida turli turli shablonlardan foydalanish imkonini beradi; bu vaqt saqlashga va bitta mashinaning turli to'plamlarni bajarishiga imkon beradi. Boshqa qayerda bir nechta ishlab chiqarish bosqichlari turli turli shablonlarga ehtiyojini talab qilsa ham, bunday hamma talablarni bitta mashina orqali oson ravishda qanoatlantirish mumkin. Uning og'ir dizayni, boshqa modellarning tez-tez yorug'likdan sababli ishlamay olishi mumkin bo'lgan murakkab sharoitlarda uzun muddat davom etgan ishlab chiqarish jarayonida ishonchli ishlashni ta'minlaydi. Foydalanuvchi uchun yaxshi interfeys va avtomatik boshqaruv operatsiyani osonroq qiladi va operatsion vositalarining to'xtash vaqti kamayishi bilan birga, cheksiz davom etadigan davrda chiqim kapasitetini oshirishni xohlagan ishlab chiqaruvchilar uchun qulay hisoblanadi. Masalan, katta miqdordagi ishlab chiqarish yoki kichik miqdordagi to'plamlar bilan ishlashda ham, ushbu qurilmalar har doim kutganidan yuqori performans ko'rsatadi, chunki uning robushtaligi shu holatlarda plastik shablonlash uchun turli xil yo'llarni qo'llab-quvvatlaydi va zarur emasligi sababli to'xtamaydi.

Zhangjiagang COMARK Machinery Co Ltd ichki ichimlik ishlab chiqarish qatorini eksport qilishda 15 yildan beri mutaxassisligini rivojlantirib kelmoqda. Biz mijozlarga PET butalik, aluminiy konserve, steklovod qutisi uchun to'liq ichimlik (suv, shirin ichimlik, gazoza, energiya ichimliklari, muz qayiq va boshqalar) ishlab chiqarish turnkey loyihalarini ta'minlaymiz.

Quyidagi xizmatlarni taqdim etishimiz mumkin:

1-to'liq ishlab chiqarish qatori uchun barcha mashinalar

(suv muammosi tizimi / aravot tizimi / yuvalash, to'ldirish, qopqoqlash mashini / lazerniy kod chap mashini / label mashini / paketlash mashini / buta transport mashini)

2-Preform, qopqoq, konserve, label, PE film kabi asosiy materiallarni taqdim etish

3-Mashinalarning o'rnatilishi haqida, bizning professional muhandislar joyiga yetib boradi, ular o'rnatishni yakunlaydi va sizning muhandisingiz va ishchilaringizni o'rganitadi

4-Sizning ish o'rinigingizga qarab, label, buta shakli va mashinalar joylashtirishini dizayn qilish mumkin

Comark Mashinasozligi ichimliklarni paketlash bo'yicha tadqiqot va rivojlantirishda birinchi sifatda yuritadi. Yuqori va past tadqiqotga qaratilgan ishlar to'liq spektrni ta'minlaydi.

30 dan ortiq davlatda xizmat ko'rsatadigan Comark, ichimliklar, mazalar, kosmetika, piva, sut va dori bo'yicha sanoatlar uchun yechimlarni taqdim etadi. Dunyo bo'yicha kuchli pozitsiya va ko'p tomonlilik ularning sanoatdagi pozitsiyasini mustaqillikka erishadi.

Comark texnik innovatsiyaga qaratilgan ishlarini davom ettirib, patentlarni tasdiqlab, unikal bo'lgan bozor pozitsiyasini rivojlantiradi. Ushbu va'da ularni ichimliklarni paketlash sohasida oldindagi sahilga qo'yadi.

Comark eng mashhur tashkilotlar bilan hamkorlik qiladi, xorijiy texnikani tahlil qilib uning elementlarini dizayn va bajarishni optimallashtirish uchun ishlatadi, namunaviy to'rtulikka erishish uchun.

14

Aug

14

Aug

14

AugCOMARK Blow Moulding mashini ko'p funksiyali va shishqonli plastik mahsulotlar, qutular, konteynerlar va xususiy shakllardagi elementlarni ishlab chiqarishi mumkin. U turli xil termoplastik materiallardan foydalanish uchun mo'ljallangan va turli muammolarga yaxshi natija beradi.

Mashinada asosiy nazorat tizimlari va sozlanadigan sozlamalar mavjud, bu esa aniq tartiblash imkonini beradi. Uning yuqori ashyoqli sensorni va avtomatik nazorat tizimi urinish va sifatni osonlashtiradi va mahsulot sifatini saqlaydi.

Ishlab chiqarish quvvati modellarga va konfiguratsiyaga qarab o'zgarishi mumkin. Har bir holatda, mashina katta hajmdagi ishlab chiqarishni effektiv ravishda bajarishi mumkin. Aniqlash uchun maxsus kapasitet ma'lumotlariga mahsulot xususiyatlari bo'limiga yoki savdo jamoamizga murojaat qiling.

Masin tarmoqlanuvchi shablon yopish va moslashtirish tizimlari bilan tenglangan, bu esa turli xil shablon o'lchamlariga va ko'rinishlariga ruxsat beradi. Ushbu esneklik, turli ishlab chiqarish bosqichlari orasida oson o'tishga va turli mahsulot qatorlari bo'yicha baland efeksiyani saqlashga yordam beradi.

Optimal ishlashni ta'minlash uchun reguliar texnik tadqiqotlar muhim. Bu mashina komponentlari haqida routin tekshirish, shablonlash sohasini tozalash va boshqaruv tizimlarining davrli kalitlanganishiga olib keladi. Masin to'liq texnik tadqiqot qo'llanmasi bilan yetadi va bizning texnik jamoamiz sizning maxsus talablaringiz uchun qo'llab-quvvatlashni taqdim etadi.