KIJZER UW OPLOSSING

VOLLEDIGE PRODUCTIELIJN

Korte introductie

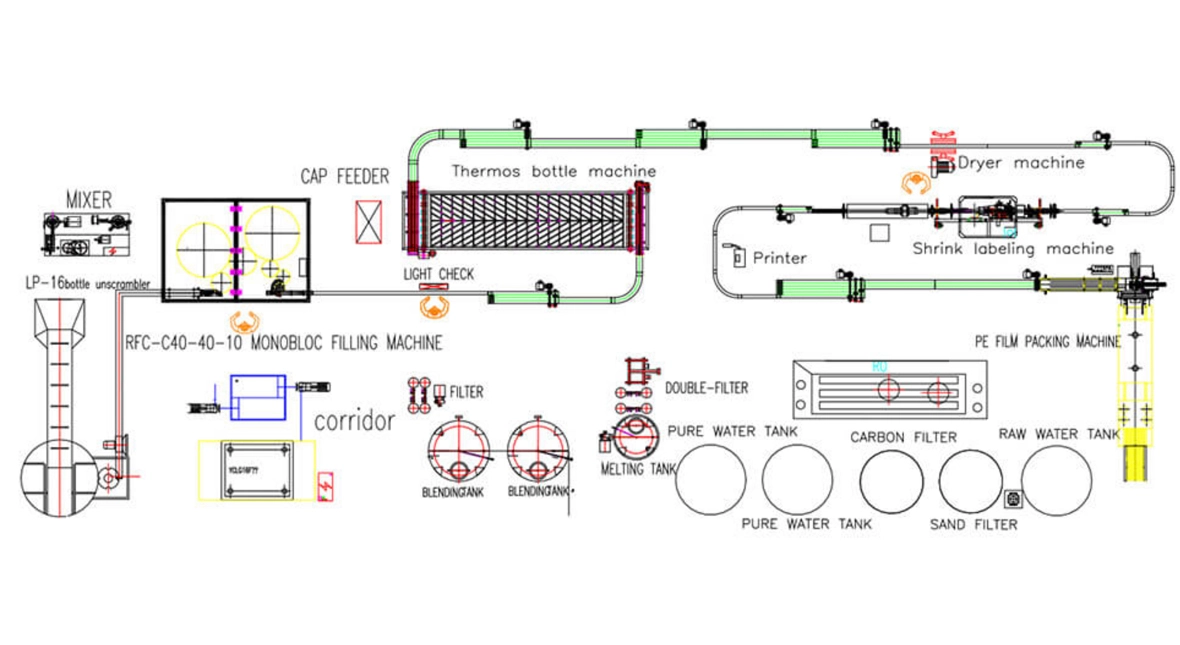

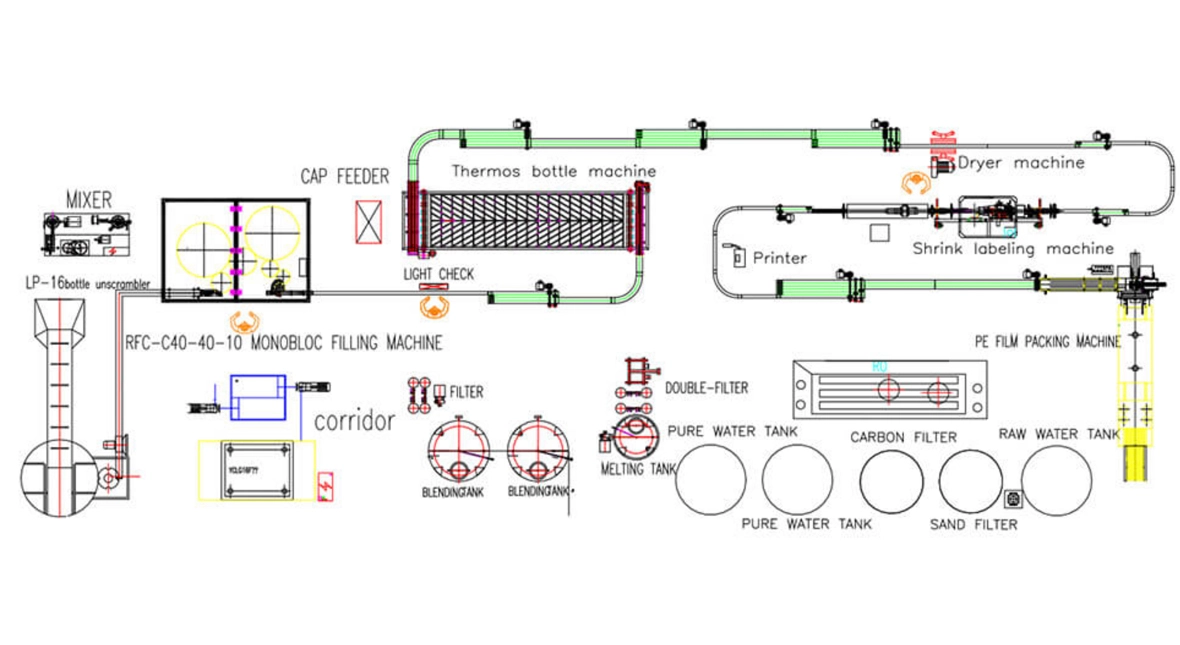

De hoofduitrusting van de productielijn voor plastic flessen sap omvat een flesblaasmachine, waterbehandelingsapparatuur, mengapparatuur voor functionele drankjes, reinigings-, vull- en afsluitmachines, verpakkingsapparatuur, enz. Er zijn veel soorten warmtegevulde dranken op de markt. Verschillende soorten hebben verschillende productievereisten. Comark Machinery zal alle mogelijke inspanningen doen om de perfecte oplossingen te bieden aan verschillende klanten en helpen klanten de markt sneller en beter te beherven.

Productielijn

CAD Configuratie

Productielijn voor sap

De RCGF-serie drankvulmachine integreert fleswassen, vullen met water en afsluiten in één monobloc, en de drie processen worden volledig automatisch uitgevoerd. Het wordt gebruikt voor warm vullen van vruchtensap, thee, energiedrankjes en andere ongecarbonateerde dranken. Het is uitgerust met een perfecte temperatuurcontrolesysteem, een terugstroom systeem, een automatisch reinigingssysteem en controleprogramma's. Elk machineonderdeel dat in aanraking komt met de vloeistof is gemaakt van hoogwaardig roestvrij staal en voedingsgradige rubber. Geen fles, geen vullen, en geen fles, geen afsluiten, automatisch en eenvoudig in bediening. Het maakt gebruik van een hangende transport-flesstructuur om het wisselen van flessenmodellen gemakkelijker, sneller en eenvoudiger te maken. De hoofdvulmachine maakt gebruik van geavanceerde PLC-technologie voor controle.

VOLLEDIGE LIJNAPPARATUUR

1.Waskop

- Met behulp van het oorspronkelijke schuine flesclip en flessenklem van het bedrijf wordt de fles hals vastgehouden, waardoor eventuele verontreiniging door de rubberclip op traditionele flessen kan worden voorkomen. De flesclip is gemaakt van SUS304 roestvast staal, wat gezond en duurzaam is.

- Met gebruikmaking van een geïmporteerd speciaal efficiënt spuitmondstuk kan het wastewater onder een bepaalde hoek worden gespoten, waardoor elk deel van de binnenwand schoon kan worden gemaakt, grondig met water wordt afgespoeld en waterbesparing bij het spoelen van de fles wordt bewerkstelligd.

2.Vulhoofd

- Het wassen, vullen en afsluiten zijn verbonden met duimradkaarten voor flessenhals transportmethoden.

- De draaischijf is geheel gemaakt van SUS304 roestvast staal.

- Vulmethode is warm vullen, waarbij temperaturen tot 85℃ kunnen worden bereikt.

- Urustgerust met een perfecte temperatuurregelsysteem en terugvloei systeem.

3.Afsluitkop

- Plaatsings- en afsluitingsysteem, elektromagnetische afsluitkoppen, met belastingafvoerfunctie om te zorgen dat er minimaal flessenbreken plaatsvindt tijdens het afsluiten.

- Volledige constructie van 304 roestvast staal.

- Geen fles, geen afsluiten.

- Automatische stop als er geen fles is.

- De effectiviteit van het afsluiten is stabiel en betrouwbaar. Defectief percentage ≤0.2% .

| Model |

Rc GF

8-8-3

|

RCGF

14-12-5

|

Rc GF

16-16-5

|

Rc GF

18-18-6

|

Rc GF

24-24-8

|

RCGF

32-32-8

|

Rc GF

40-40-10

|

Rc GF

50-50-15

|

Capaciteit

(voor 500ml)

|

2000 per uur |

4000BPH |

8000 per uur |

6000BPH |

10000BPH |

12000 BPH |

15000BPH |

20000BPH |

| Toepassing |

Sap\/Hete thee\/Energiedrank |

| Vermogen |

3.01 kw |

3.75 kW |

5.05 kW |

5.03 kW |

6.57 kW |

8.63 kW |

10.68 kW |

12 kW |

Totale afmetingen

(mm)

|

2000*1800*2250 |

2100*1800*2250 |

2760*2060*2250 |

2360*1830*2250 |

2900*2200*2250 |

3880*2200*2250 |

3700*3000*2350 |

4500*3300*2350 |

| Gewicht |

2000kg |

2000kg |

3800kg |

2500kg |

4200kg |

6000kg |

7000kg |

9000kg |

| Leveringstijd |

30 werkdagen |

| Geschikte flesvormen |

PET rond of vierkant |

| Flesdiameter |

50-120 MM |

| Fleshoogte |

150-320 MM |

| Compressorlucht |

0.3-0.7 Mpa |

| Wasdruk |

0.06-0.2mpa |

VOLLEDIGE LIJNAPPARATUUR

Automatische Blaasvorm Machine

Het produceert de plastic PET fles die gebruikt kan worden voor frisdrank, mineraalwater, sap, olie en andere warm invulbare vloeistoffen. Deze machine is zeer populair over de hele wereld vanwege het lage investeringsbedrag maar goede effectiviteit bij het blazen van PET flessen. We kunnen verschillende snelheden van flesblaasmachines produceren volgens de eisen van de klant. De flesblaasmachine kan worden ontworpen met één holte, twee holen, vier holen, zes holen etc., en ook kan hij worden ontworpen met semi-automatisch, handmatig invoegen automatisch en volledig automatisch etc.

Waterzuiveringssysteem

- Het omgekeerd osmoseapparaat is een installatie om zout water te zuiveren door gebruik te maken van de drukverschil van een halve doordringbare membran.

- Meer dan 97% oplosbare zouten en 99% lijm, microbiële, deeltjes- en organische stoffen enz. kunnen met behulp van omgekeerde osmose worden verwijderd. Het is het meest ideaal apparaat voor het moderne programma van zuiver water, ultrazuiver water en ruimtevaartwater.

- Het wordt omgekeerde osmose genoemd omdat het tegengesteld is aan de natuurlijke doordringingsrichting. Verschillende materialen hebben verschillende osmotische drukken. De methode van omgekeerde osmose gebruikt een hogere osmotische druk om het doel te bereiken van scheiden, extraheren, zuiveren en concentreren.

- De opvallende kenmerken van de installatie zijn lage energieverbruik, geen verontreiniging, eenvoudige technieken, hoge waterkwaliteit, gemakkelijke bediening en onderhoud.

- Na behandeling door RO kan water de vereiste fysische en chemische indicatoren voor drink- en hygiëne normen bereiken, wat schoon zuiver water oplevert dat de beste keuze is voor lichaamshydratatie. Het is een belangrijk apparaat in de productielijn van een zuiverwaterfabriek.

- Osmoseomkeringstechnologie is een goed ontwikkelde desalinerings technologie ter wereld, en het is ook de meest breed toegepaste en toepasbare watertechnologie op de markt. Het heeft een lage werkdruk, grote waterproductie, hoge zoutafwijzing en is gemakkelijk te onderhouden.

Sapverwerkingsysteem

-

SUiker- / RAuw MATERIAAL OPLOS SISTEEM

Hoog-scheermixtank / Centrifugaal pomp / Dubbelzakfilter

Plaatwarmtewisselaar / Elektrisch kastje / CIP retourpomp

-

MENG SISTEEM

Rauwmateriaalomsetank / Centrifugaal pomp

Dubbelbuisfilter / Elektrisch kastje / CIP retourpomp

-

BUISSTERILISATIE EN HOMOGENISEERSYSTEEM

Buistotale automatische sterilisator / Vacuümdegasser / Homogeniseerder

Sapopslagtank / Centrifugaal pomp / Elektrische kast / CIP terugpomp

CIP-systeem

- Zorg voor een bepaald reinigings-effect, verbeter productveiligheid.

- Bespaar bedieningstijd, energie en arbeid, verhoog efficiëntie.

- Het kan grote schaalproductieapparatuur bereiken, hoge mate van automatisering.

Koeltunnel

- Als de temperatuur te hoog is bij het vullen van de drank, kan deze machine geïnstalleerd worden na de vullmachine om de temperatuur te verlagen.

- De continue spuitsterilisator is ontworpen en gemaakt op basis van het absorberen en verwerken van buitenlandse machines.

- Het gebruikt warm water om voor te verwarmen, steriliseren met herbruikbaar heet water, herbruikbaar warm water om voor te koelen, en koelwater om af te koelen.

Automatische Laser Printer Machine

- Goede straal kwaliteit, TEM00 enkelvoudige modus uitkomst, straal diameter 10mm na collimaties, M2<1.3, straaldivergentiehoek 0.24mrad;

- Na focusseren, is de vlek diameter klein en de piek vermogen dichtheid op het werk punt zeer hoog (109W/cm2), wat zeer geschikt is voor fijn aanduiden, boren en andere toepassingen.

- Hoge puls herhalingfrequentie (20-60kHz); Zeer geschikt voor hoge snelheid markeren.

- Hoofd-osculatie vermogen versterkingstechnologie zonder onderhoud en puls generatietechnologie van zaadlichtbron; Hoge betrouwbaarheid, gemiddeld zonder storingen.

Warmlijm opp labeling machine

- De coderingsmachine wordt voornamelijk gebruikt voor het labelen van containers met cilindrische, vierkante of andere speciale vormen van reinigers, dranken, mineralenwater, voedsel, etc.

- De coderingsmachine wordt bestuurd door een PLC-touchscherm, alle elektrische ogen gebruiken geïmporteerde geavanceerde configuratie.

- Hoge snelheid, hoge precisie, stabiele prestaties.

- Gemakkelijk te bedienen en een elegante uiterlijk.

Automatische Schrink Verpakkingsmachine

- Compact & artistiek ontwerp. De constructie is nieuw en uniek.

- Elektronische inductieve voedingsfilm, de beweging is gebalanceerd en het vervangen van de film gaat snel.

- Isotherme afsluitmes. De sluitsterkte is meer dan driemaal zo sterk als bij koelingsluiters, de sluiting is gelijkmatig en de levensduur is meer dan 80 keer langer dan bij koelingsluiters.

- Transport systeem met frequentieregeling, de transmissiebeweging is nauwkeurig en gesynchroniseerd.

- De krimpkuub gebruikt een centrifugale thermische luchtcirculatie systeem, de opbouw is logisch, warmte-isolatie en warmte-bewaring, de thermostaat precisie is hoog en het verpakkingsresultaat is beter.