Sistema ta' trattament tal-ilma

■Sistema ta' pre-trattament (tanx tal-ġimgħa \/ filtri multi-medju \/ filtri ta' karbon attivi \/ scambjaturi jonici \/ filtri preċijsi)

■Sistema ta' separazzjoni membrana (filtri superfiltranti \/ filtri nanometriki \/ sistema RO osmosi inversa)

■ Aparat ta' elettrodialisi \/ Sistema ta' sterilità (deċiv UV, apparat ozon) tanx produtt tal-ġimgħa u ċiek.

■Mašina ta' immodellatur 1,000-24,000bph, u bidliet PET ta' 0.25-2L huma disponibli.

■Tista' tistgħu lierament għall-iproduzzjoni tal-bidla karbonata, l-ġenja tal-minerali, bidla ta' ħeluwa, bidla ta' insektizidi, bidla ta' kosmetika, bidla twil-għolja u bidla li jippermettu il-maltija, itp.

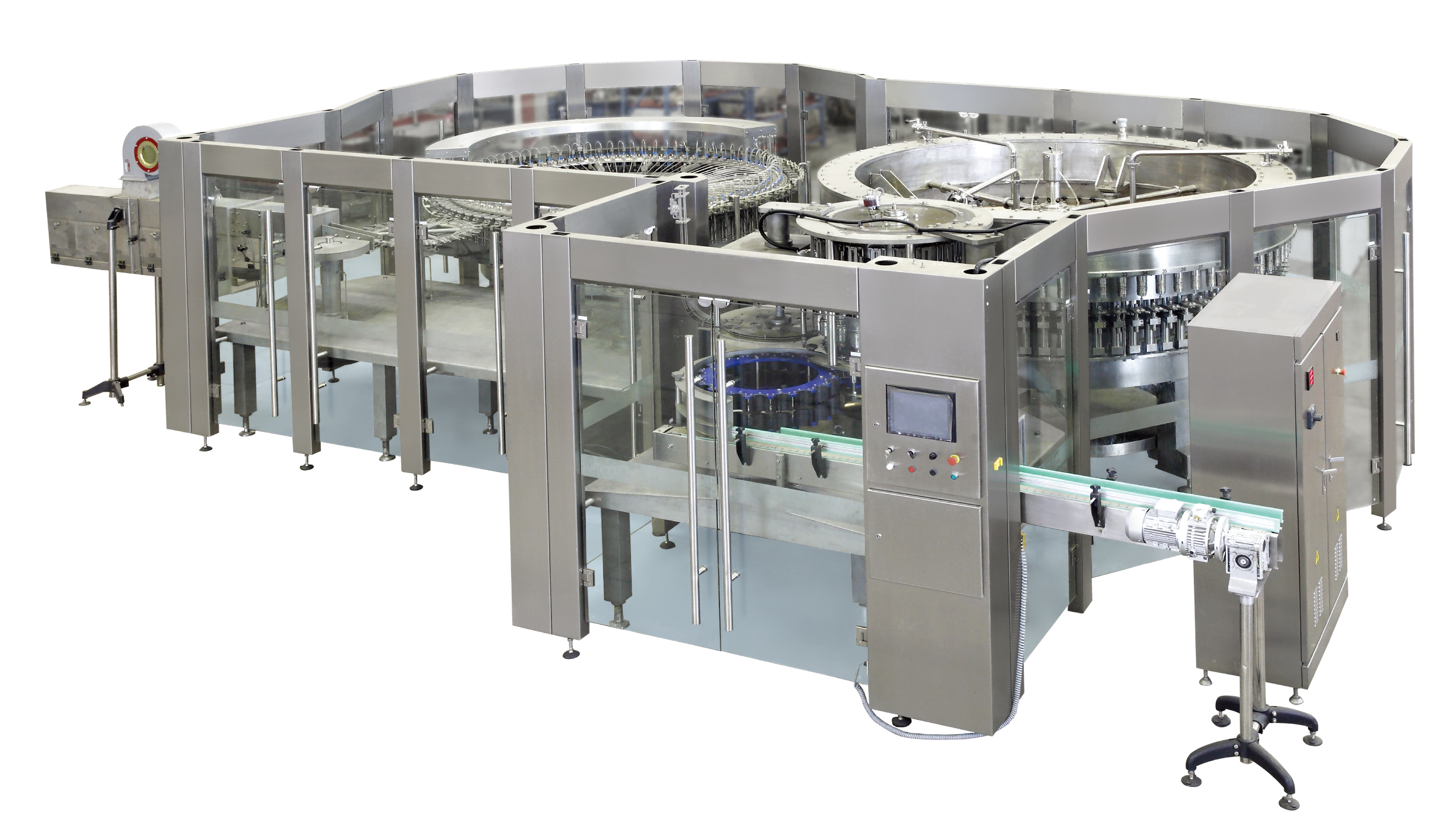

■L-intrfjiċ tal-ġimgħajjed u l-ommannanti hija altament awtomatizzata u ssegħa għall-operazzjoni.

■Il-mašina kompakta tagħti spazju aħjar.

■Is-sistema ta' proċessar tal-bivanda japplicja għal il-proċessar tal-bivanda għall-linja ta' maltija u linja ta' is-silliment.

■ P skop produtt: sistema ta' miż-ħamra, sistema ta' sbħin tal-ġul (sistema ta' sirup sinpliċi), sistema ta' konċentrat, sistema ta' mixjar (sistema ta' sirup finali), sistema CIP, sistema ta' estrazzjoni, varjetà ta' tanċi tal-ħfod / vallijiet / tubi / fitting, sistema UHT (tip ta' plaċċa / tubolar), u carbo-cooler / mixer (manwali / awtomatiċi).

■ Jista' jiġi dizajnat u jagħmlu skont iċ-ċondizzjonijiet ta' sterilità u produzzjoni li jirrid il-klijent.

■ Il-sterilizzatur tal-ispirt tal-kontinwiġ hija dizajnata u ikkrija fuq is-sors ta' absożew u diġestjar ta' mašiċi stranieri.

■ Għandha l-avvantaggji ta' kontroll awtomatiku ta' temperatura ta' sterilizzazzjoni u żmien ta' sterilizzazzjoni ażjustabbli.

■ Tista' tiservi fl-istieri għall-sterilizzazzjoni u sfiħ ta' suċċi u bevandi f’diversi botli u kani, bevanda elettrolitika, vino u speċjali.

■ Id-drittija hija biss li jkollha l-ommertijiet tal-pakkjażġġ tal-kontenenti cilindrici, kvadrati jew oħra formi speciali ta' deterdenti, bevandi, acqua minerali, ħaddiema, ecc.

■ Veloċi, preciżi u perfurmans stabli.

■ Semplice biex tirrappruva u apparenza eleganti.

■ Il-mašina ta' pakkjażġġ fil-film PE hija adatta għall-pakkjażġġ ta' prodotti kif l-aqu minarali, birra tal-botli, bevandi, itp mingħajr base-traj (jew b'sess base-traj).

■ Ttrabaja mal-tunel ta' kontraqqta PE biex tpakkja l-merkanti perfettament. L-iklru produttiv proċess huwa bażat fuq teknoloġija avvanzata tal-Ġermanja.