Plastic bottle blow machine is an indispensable equipment for making plastic bottles. These machines supply the different shapes and sizes of bottles we see every day. From water bottles to detergent containers, the machines are an essential cog in making the stuff we use. Heated plastic tubes are inflated with air to mold the shape of the bottle. You can find very fine companies that include COMARK making machines of this kind and selling all sorts to fit the different needs when manufacturing.

There is so much to consider when buying a plastic bottle blow molding machine. First, the machine's size matters. You don’t need a big machine if all you are using it for is smaller bottles, but if you have a plant designing jumbo-sized plastic containers, an oversize press is necessary. The machine speed is also a factor. There are machines that can churn out bottles fast, and others that can be slower but perhaps result in better-quality ones. You’ll need to strike a balance between speed and quality.

Next, analyze the features of the machine. Some extrusion blow machines are better with the new technology on how to manage the process. For instance, machines that have digital displays can make it simple for operators to find their desired settings. Also, see if the machine is easy to clean and maintain. Cleaning is no fun, so any ease in access to the parts is a time saver. Furthermore, understanding the type of Material that the machine can process is crucial for optimal performance.

Another is what the machine can process material-wise. There are different types of plastic with which to do this, and some machines work better with certain types than other ones do. Just verify which kind of plastic will work with your machine. Plus, manufacturer support and service is important. A company such as COMARK has excellent customer service and this can be useful if you have a problem or questions about the machine. When considering options, you might also explore alternatives like a Injection Moulding Machine for different manufacturing needs.

Another excellent means to locate the equipment at reduced prices is by searching for wholesale suppliers. Companies like COMARK, for example, may extend wholesale prices to businesses that are looking to purchase more than one machine. Purchasing in bulk can also be a big money-saver. By all means contact suppliers with whom you may have a relationship to ask about discounts or specials.

When you are seeking out dependable plastic bottle blow molding machines wholesale, it is essential that you know where to get high quality equipment. And one of the best ways to get started is by attending trade shows and conventions. These events bring together scores of manufacturers and suppliers under one roof, making it easier to lay eyes on various machines and talk with the people who make them. At trade shows, you can often watch the machines run, helping you understand how they work. Online marketplaces are also a great resource. Many sites that cater to industrial equipment will have a blow molding machines section. You can read descriptions, compare prices and even find reviews from other buyers. You might want this information to take a reasonable decision. You should also reach out to the suppliers themselves and be smart about it. Firms like COMARK are good sources for high end machines. You can inquire about their products and find out information on pricing and availability. Several suppliers have a sales department that can assist you in choosing products on the marketplace. You can also join industry groups and forums on social media. Speak With other people in the industry can provide you with ideas where to get excellent machines. They may suggest options you didn’t know about, or share with you their experiences with various brands. Finally, try to find manufacturers who offer warranties and customer service. This means that they believe in their products and are willing to assist you if any issues should arise. When it comes to a plastic bottle blow molding machine, you need to find one that you can count on and making the right decision is essential for your business.

But as technology continues to evolve, there are some pretty cool changes in plastic bottle blow molding that buyers should consider. One of the most obvious trends is to use machines with good energy efficiency. These machines requires less electricity, which also saves money and is good for the environment. There are many companies that are trying to minimize their carbon footprint and using energy-efficient blow molding machines is certainly a step in the right direction. Another significant novelty is represented by the production of machines able to manufacture bottles with different shapes and sizes. Such flexibility gives businesses the ability to build unique products that provide a competitive edge. Some horizontal machines, for instance, can move from producing a small bottle to making a large one quickly and without requiring much additional tweaking. This is a time and money saver for producers. There is also the fact that automation is coming on in leaps and bounds. New machines can also be set up to operate automatically, meaning some of the manual labour can be cut down. This does not only accelerate work, but also decreases errors. COMARK is leading the way in these technology improvements, offering machines that incorporate the newest capabilities for increased productivity. There are also innovations in materials that buyers should be aware of. There are new plastics, stronger and lighter than ever. These make the quality of the bottles better and also more environment friendly. Finally, intelligent technology is coming to blowmolding machines. This allows machines to be connected to the internet and monitored from afar. Operators receive alerts immediately if there is a problem, which means that fixes can be made rapidly. By learning about these developments, buyers can identify which machines will work best for their needs and give them a competitive edge.

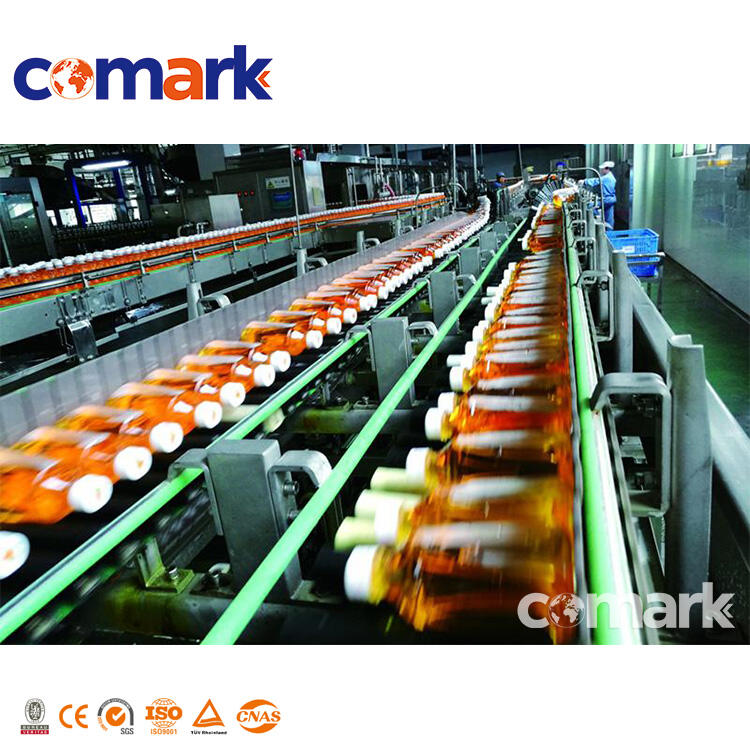

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.