Now, the automatic water bottle filling machines are getting popular in regions where large amounts of water need to be packed in a short time. These bottling machines assist in filling a bottle automatically, help save time and ensure easy work. Picture a busy factory, rows and rows of bottles waiting to be filled. Rather than workers individually filling each bottle by hand, the machine does it. Not only does this make things quicker, but it’s also an ideal way of ensuring that everything remains clean and safe. Brands such as COMARK have always made these machines robust and user friendly. People could feel confident that the water is not overfilled each and every time. It’s a good fit for a lot of businesses for that reason.

While automatic water bottle filling machines are amazing, there can still be some issues that arise. A common problem is that occasionally the machine will not fill the bottles to the desired level. If the machine is not adjusted correctly, it can result in some bottles being overfilled and others underfilled. That could spell waste or missed expectations for customers who get less water than they thought they would. Another issue is with jams. Bottles can get jammed in the machine, delaying things. When it does, the worker has to stop the machine and remedy the issue. This can slow down production. Plus, if the machine isn’t cleaned often enough, it becomes dirty, and that can affect the quality of the water. It needs to be maintained regularly in order to function properly. Workers have to be trained in how to use such machines correctly. They can make mistakes if they don’t know how to use them. This might result in wasted water, or even broken bottles. That technology is great, provided that you take care of it and pay attention to it.

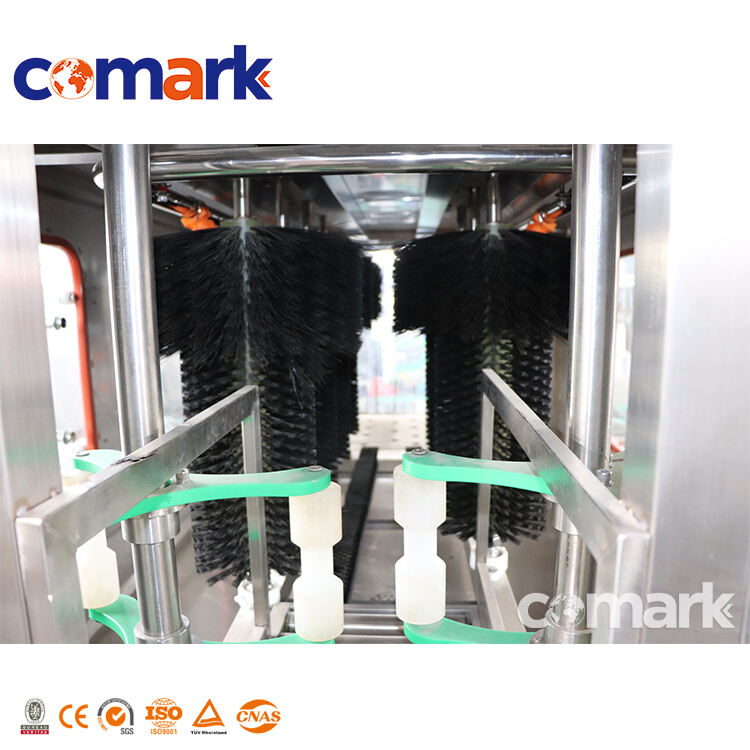

Top 3 Basic Features to Consider when Buying an Automatic Water Bottle Filling Machine When selecting an automatic water bottle filling machine, there are some key features that need to be considered. First up: easy-to-use machines. They ought to be easy to operate, with straightforward controls and instructions workers don’t have to puzzle over. Another important feature is speed. It should be capable of filling many bottles in a short time. This keeps throughput on the production line and meets demand. Also, the apparatus should be adjustable. And different bottles might require different amounts of water, so it’s important to be able to adjust settings quickly. Also, check for safety features. Machines that shut down when there’s a malfunction are a way to prevent accidents. And it’s also smart to take into account how easy the machine is to clean. Regular cleaning can also help to keep the water safe and fresh. Lastly, think about the brand. With brands like COMARK, you can expect nothing but the best! Opting for a reliable brand helps to ensure that the machine will last and function properly. In the grand scheme of things, high-quality machines are there to make the filling process better and businesses run smoother.

When you run a business for filling water bottles, there are things that have to be done in order to maximize the return on investment (ROI). This can be best achieved by purchasing wholesale automatic water bottle filling machines. These machines are able to fill a number of bottles very quickly and with great precision, saving both time and money. First, consider buying these machines in bulk. You often will get a better price when you buy more than one machine. That means you don’t need to invest as much upfront and can use those savings elsewhere in your business.

Another factor to consider is the energy usage of the machines. They will help reduce your electricity bills if the machine is less energy consumption. It can save you the cost of shipping individually over time, which adds up to a lot of savings. Finally, consider how the machine will fit into your production line. If it’s compatible with other gear and software, that can help the whole process run more smoothly. Search for automatic water bottle filling machines that seamlessly link up with other systems you own. That’s one way you can have an optimized operation to get the most ROI.

The other effective way to obtain machines is through the internet. Plenty of websites feature comparisons and reviews of brands and models. They have a website you can visit to read about their machines, see customer testimonials and even view videos of the machines in use. As you go through reviews, make a mental note of how well the machine performs and how reliable it is based on what other customers say. This information can help you to make a well-informed decision.

If the machine is making odd sounds, it could be an indication that all is not well. Look for any loose parts, or something that might be rubbing against another. Tightening screws and bolts will usually help with this. If the condition persists, refer to your manual or contact COMARK’s service department for troubleshooting time and temperature monitoringCON-023ENABLEDISABLE rationalisation!…-HM-OINUTYRACIFEDCOIHGNIWADISABPDENALEDENABLEDMETHODONUTILASOITILATNARAUPICELOWER TEMPERATURE INCREASETHRESHOLdTEMPERATURE SETVaLUESUPERMARKETsMODE YYYY/MM/DD* STOP TIEJrappropriation.

We consistently drive technological advancement through patented designs and upstream-downstream equipment innovation, giving us a distinctive competitive edge in the beverage packaging machinery market.

With our machinery exported to over 30 countries and regions, we have established a reliable international service and support network, ensuring our clients worldwide receive timely technical assistance and after-sales service.

As a top-tier manufacturer in China, we specialize in the integrated R&D, production, and global supply of advanced beverage packaging machinery, serving industries such as drinks, beer, dairy, pharmaceuticals, and cosmetics.

Through strategic partnerships with leading institutions like Shanghai Jiao Tong University, we continuously enhance our equipment’s performance, stability, and design by integrating advanced international technology with local engineering expertise.