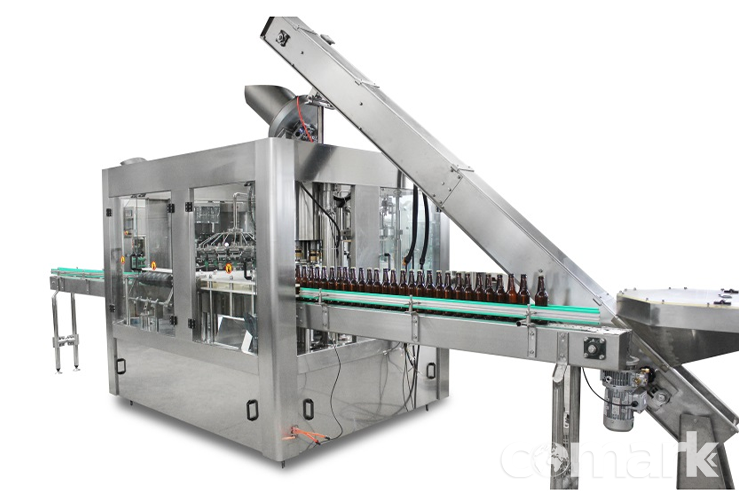

Complete Automatic 16000BPH Glass Bottle Beverage Production Line

Description

Complete Automatic 16000BPH Glass Bottle Beverage Production Line

The machine combines washing, filling and capping three function in a body,used to produce plastic bottled juice,energy drink and hot tea machinery. The whole process is automatic, Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient.

Technical Parameters

Model(BCGF) |

14-12-5 |

18-18-6 |

24-24-6 |

32-32-8 |

40-40-12 |

50-50-12 |

60-60-15 |

Washing heads |

14 |

18 |

24 |

32 |

40 |

50 |

60 |

Filling heads |

12 |

18 |

24 |

32 |

40 |

50 |

60 |

Cappping heads |

5 |

6 |

6 |

8 |

12 |

12 |

15 |

Capacity(BPH) |

2000 |

3500 |

5000 |

8000 |

12000 |

16000 |

20000 |

Power(kw) |

2.2 |

3.5 |

4.5 |

6 |

7.5 |

9.5 |

11.2 |

Dimension(mm) |

2400*1600*2500 |

2600*1920*2550 |

3100*2300*2800 |

3800*2500*2900 |

4600*280082900 |

5450*3300*2900 |

6500*4500*2900 |

Weight(kg) |

2500 |

3500 |

4500 |

5600 |

8500 |

9800 |

12800 |

Main Features

1. Touch screen operation interface.

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

3. The filling accuracy can reach ±0.2%.

4. With no bottle no flling and automatic bottle stop function.

5. Design different positioning devices according to the actual situation of the bottle.

6. PLC programmable control use Japan Mitsubishi.

7. Material contact parts are made of SUS304# stainless steel.

Water treatment system

It is mainly composed of the following equipments:

1> Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter)

2> Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system)

3> Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on.

4> Used for pure water,mineral water and other bottled water,water for food and beverage production.

Beverage Pre-treatment System

1> The beverage processing system applies to beverage processing for hot filling line and CSD filling line.

2> product's scope hot water system, sugar dissolving system ( simple syrup system ), concentrate system, blending system (final syrup system), CIP system, extraction system, kind of storage tank / valves / pipe / fittings, UHT system (plate / tubular type), and carbo-cooler / mixer (manual / automatic).

1> Juice filling line production capacity is usual in 1,000-36,000bph, 0.25-2.5L PET bottles are available.

2> Juice filling line can apply to fill fruit juice, energy drink, hot tea drink into PET bottle by changing few spare parts.

3> Automatic juice filling machine adopts rinsing, filling and capping 3-in-1 technology, PLC control, touch screen. It is mainly made of SUS304/ SUS316.

4> Pivotal electrical parts adopt Mitsubishi, OMRON, and SIEMENS for juice filling production line.

5> The whole production filling line accuracy is more or less than 1%.

Bottle cooling tunnel

1>It is with the advantages of sterilizing temperature automatic control and adjustable sterilizing time.

2> It can be designed and made to the sterilization conditions and production provided by the customer.

3> It can be widely used in sterilizing and cooling of juice and beverage in various bottles and cans, electrolyte beverage, wine and condiments. It adopts warm water to preheat, sterilize with recycling hot water, recycling warm water to pre-cool, and cooling water to cool.

4> The machine adopts a temperature control system with high temperature control accuracy and sensitive response. Press the button of the temperature control table to set the temperature, which can be changed arbitrarily within the range of 0-100°C

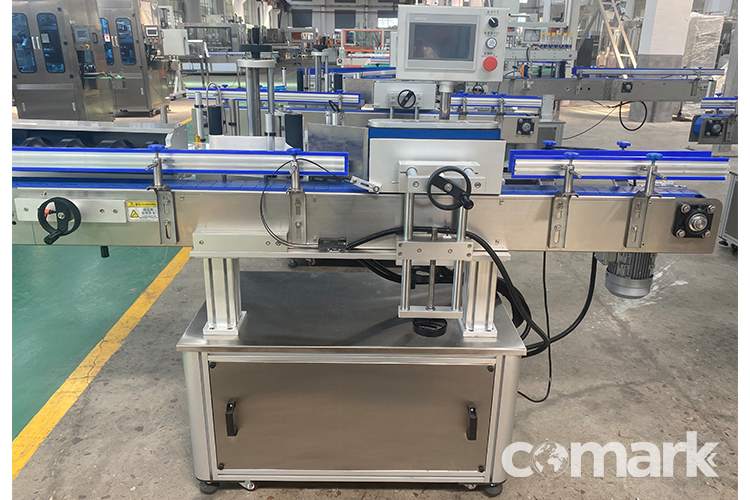

Adhesive sticker Labeling Machine

Round bottle sticker labeling machine incorporates latest sophisticated User Friendly Label Dispensing applicator System with choice of Stepper or Servo Driven System. Machine with High speed Label Sensor Facility and unique Product Sensor which does not require any Teaching or settings. The Machine is suitable for Labeling on Round Vials, Bottle, Jars and other round objects. It is available with speed range of 1-30 Products per minute depending on product diameter and label size.

Automatic PE Film Shrink Wrapping Machine

1> Compact &artistic shape. The frame is novel, unique.

2> Electronic induction feeding film, action is balanced and quickly replacing film.

3> Isothermal sealing cutter .The seal intensity is above cooling sealing cutter 3 times, the seal is even and the life is above cooling sealing cutter 80 times.

4> Transport system with speed regulation by frequency variation, the transmission action is precise and synchro.

5> The shrinkage chamber uses centrifugal thermal air circulation system, configuration is logical, heat insulation heat preservation, thermostat precision is high and the packing effect is better.