Машина для консервирования COMARK предлагает идеальное сочетание эффективности и универсальности для современных операций по консервированию. Разработанная для работы с широким ассортиментом продукции, машина COMARK превосходно справляется с различными размерами и типами банок, что делает ее идеальной для компаний с динамическими производственными потребностями. Ее передовые технологии обеспечивают быстрое наполнение, укупорку и маркировку, сокращая время производства и увеличивая выход продукции. Интуитивные controls и модульный дизайн машины позволяют легко адаптироваться к разным спецификациям продукции и операционным требованиям. С помощью COMARK предприятия получают доступ к надежному решению для консервирования, которое не только соответствует высоким стандартам производства, но и предоставляет гибкость для адаптации к меняющимся рыночным запросам.

Устройства для консервирования, производимые COMARK, известны своей точностью, обеспечивая то, что каждый контейнер заполняется полностью и правильно герметизируется. Для достижения единства и превосходства во всех партиях Машина для Консервирования COMARK использует современные методы и точные системы управления. Она минимизирует потери за счет точности, гарантируя соблюдение строгих требований к качеству для каждой банки. Детальные калибровки этой машины в сочетании с высокой скоростью позволяют достичь правильных объемов наполнения, а также надежной герметизации, что улучшает безопасность продукта и одновременно повышает удовлетворенность клиентов. Предприятия, интегрирующие точные технологии от COMARK, могут производить консервированные продукты, зная, что они непревзойденны с точки зрения точности.

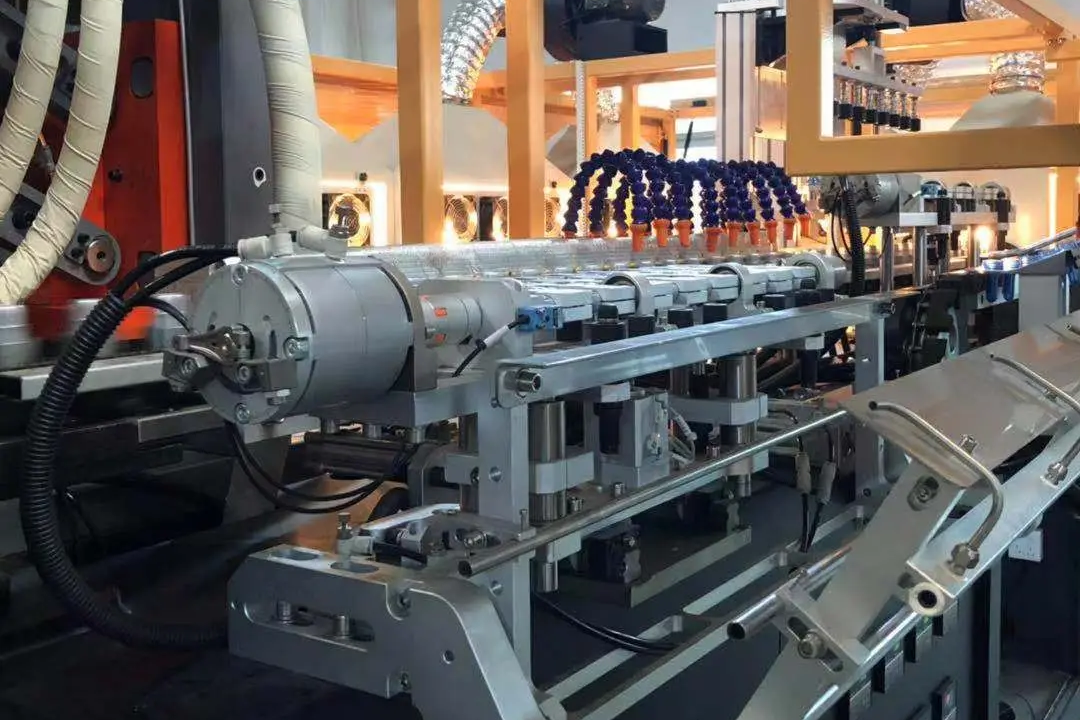

Приверженность COMARK долговечности и надежности видна в том, как они проектируют свои консервные машины. Эти машины изготовлены из высококачественных материалов и предназначены для интенсивного использования, поэтому даже в условиях высокой производительности, как в этом случае, они прослужат очень долго. Они достаточно прочны, чтобы работать непрерывно без потери качества или производительности. Эта надежность также подтверждается строгими испытаниями во время производства, а также последующими проверками для обеспечения того, что все единицы техники соответствуют стандартам операционного превосходства. Когда предприятия выбирают COMARK, они получают надежное оборудование, которое редко ломается и не требует частого обслуживания.

Для повышения удобства использования консервных машин COMARK ставит этот аспект на первое место во время процесса проектирования. Основное внимание они уделяют операционной эффективности своих машин, а также упрощению их эксплуатации. Консервная машина COMARK имеет пользовательский интерфейс, который упрощает настройку, работу и обслуживание. Операторы могут легко переходить между различными функциями машины без значительной подготовки, так как её управление интуитивно понятно и имеется четкий дисплей. Кроме того, такой дизайн обеспечивает быстрый доступ при выполнении рутинных задач по обслуживанию, что снижает простои и поддерживает машину в хорошем рабочем состоянии. Благодаря этому предприятия могут достигать высоких уровней производительности с минимальными перерывами в работе, что делает это устройство подходящим для использования в различных производственных условиях в зависимости от потребностей.

COMARK лучший в внедрении улучшенной автоматизации в свои консервные машины, чтобы сделать производственные процессы плавными и эффективными. Консервные машины COMARK оснащены передовыми технологиями, которые упрощают все этапы консервирования, такие как наполнение, запечатывание и маркировка. Они заменяют человеческий труд машинами, которые реже допускают ошибки, обеспечивая тем самым единообразие продукции. Эта машина также имеет программируемые контроллеры, связанные с системами реального времени, что позволяет точно настраивать параметры и быстро реагировать, повышая эффективность во время производственного процесса. Более того, такая высокая степень автоматизации не только увеличивает производительность, но и снижает операционные расходы за счет повышения надежности методов и уменьшения потребности в сотрудниках.

Компания Zhangjiagang COMARK Machinery Co Ltd специализируется на экспорте линий по производству напитков уже 15 лет. Мы специализируемся на предоставлении клиентам полных проектов под ключ для производства напитков (вода, сок, газированные напитки, энергетические напитки, холодный чай и другие) для PET-бутылок, алюминиевых банок, стеклянных бутылок.

Мы можем предложить следующие услуги:

1-все машины полной линии производства

(система водоподготовки / система смешивания / машина для мытья, розлива и закупорки / принтер лазерной маркировки / машина для нанесения этикеток / упаковочная машина / транспортер для бутылок)

2-Предоставление сырья, такого как преформа, крышки, банки, этикетки, пленка PE и т.д.

3- Что касается установки оборудования, у нас есть профессиональные инженеры, которые выезжают на место, они выполнят монтаж и обучат ваших инженеров и рабочих.

4-Можем разработать дизайн этикетки, форму бутылки и планировку оборудования согласно вашему цеху

Comark Machinery возглавляет РИД в области упаковки напитков, предлагая комплексные решения. Преданность исследованиям верхнего и нижнего потока обеспечивает полный спектр предложений.

Обслуживая более 30 стран, Comark удовлетворяет потребности различных отраслей, таких как напитки, ароматизаторы, косметика, пиво, молоко и фармацевтика. Глобальная доступность и гибкость укрепляют их рыночную позицию.

Comark сосредотачивается на технологических инновациях, подает заявки на патенты и создает уникальную рыночную позицию. Эта приверженность помогает им оставаться впереди в упаковке напитков.

Comark сотрудничает с ведущими учреждениями для анализа и внедрения зарубежных технологий, оптимизируя дизайн и производительность для значительного улучшения.

14

Aug

14

Aug

14

AugКонсервная машина COMARK универсальна и может обрабатывать различные продукты, включая напитки, пищевые продукты и другие жидкие или полужидкие содержимое. Ее регулируемые настройки позволяют легко адаптироваться к различным типам продукции и размерам банок.

Машина оснащена передовой технологией, которая обеспечивает точный контроль над процессом консервирования. Функции, такие как автоматическая заливка, упаковка и контроль давления, помогают поддерживать высокие стандарты качества и последовательные результаты на протяжении всего производства.

Производительность зависит от конкретной модели и конфигурации машины. Обычно она разработана для эффективной обработки больших объемов продукции. Для получения подробной информации о производительности обратитесь к техническим характеристикам продукта или свяжитесь с нашей службой продаж.

Машина имеет регулируемые механизмы, которые позволяют ей адаптироваться к различным размерам и типам банок. Эта гибкость достигается благодаря легко заменяемым частям и настройкам, что обеспечивает плавные переходы между различными сериями производства.

Регулярное обслуживание включает плановые проверки механических и электрических компонентов, очистку зон упаковки и калибровку систем наполнения и герметизации. Машина поставляется с подробным руководством по обслуживанию, а наша техническая служба поддержки доступна для любой дополнительной помощи.