12000BPH Linie de producție completă de îmbuteliere de băuturi răcoritoare cu carbonat

Descriere

Utilizare simplă, de încredere, Linie de producție a mașinilor de umplere automată pentru boute-uri cu băuturi carbonatate

Această unitate DCGF Wash-filling-capping 3-in-1: Mașinerie pentru băuturi este folosită pentru a produce băuturi gazeuse în sticle de poliestere, băuturi gazeuse și alte băuturi carbonatate mixte. Unitatea DCGF Wash-filling-capping 3-in-1: Mașinerie pentru băuturi poate finaliza toate procesele, cum ar fi presarea sticlei, umplerea și inchiderea, reducând timpul de contact al materialelor și al străinilor, îmbunătățind condițiile higienice, capacitatea de producție și eficiența economică.

Structura de transport suspendată pe gâtul sticlei asigură stabilitatea sticlelor în condiții de mișcare la viteză ridicată și face schimbarea modelului de sticlă mult mai ușoară. Interfața om-mașină cu ecran tactil și programul PLC o fac pe aceasta să fie o producție automatizată la un nivel ridicat. Toate părțile care au contact direct cu apă sunt fabricate din oțel inoxidabil de înaltă calitate. Componentele electrice principale provin din companii internaționale famosoase, cum ar fi Mitsubishi Schneider, Omron.

| Model | DCGF12125 | DCGF18186 | DCGF24248 | DCGF323210 | DCGF404012 | DCGF505012 |

| capete pentru spălare, umplere și inchidere cu capac | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 |

| Capacitate de producție (B/H) | 2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 |

| Puterea motorului ((kw) | 2.2KW | 2.2KW | 3KW | 5.5kw | 7.5KW | 11KW |

| Greutate (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 |

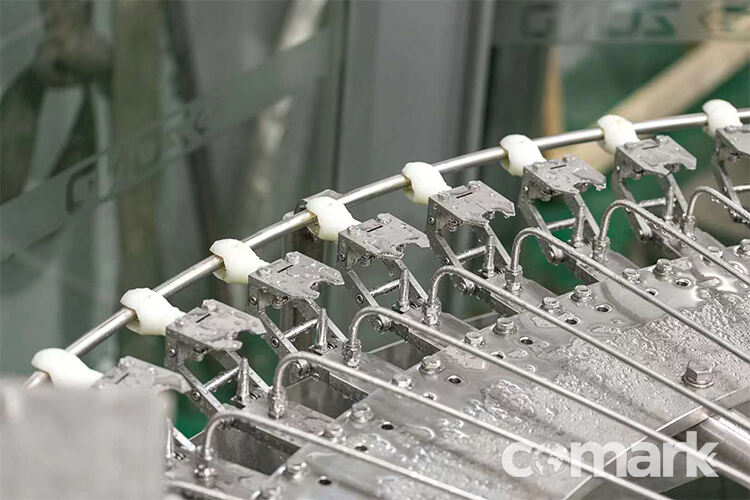

- Partea de spălare

1. Roua rotativă este o structură complet sudată din oțel inoxidabil.

2. Toate buștile de alunecare ale dispozitivului de ridicare folosesc arcuri Igus (Germania) anti-corozive fără necesitate de întreținere.

3. Spălătoarea este accionată de sistemul de propulsie situat în interiorul cadrului mașinii prin transmisie cu roua dințată.

4. Mașina utilizează un șinchet unic de golire a sticlei, care reprezintă o inovare a companiei noastre. Acest șinchet捉sticle la poziția gâtului, evitând contaminarea treptei de la gura sticlei cauzată de blocul de gumă al șinchetului tradițional. Fabricat din oțel inoxidabil SUS304, acest șinchet este higienic și durabil.

5. Uscătoarea cu atomizare de înaltă eficiență montată pe șinchet poate curăța orice parte a pereților interni ai sticlei și economisește, de asemenea, apa de spălare.

- Piesa de umplere

1. Roua rotativă este fabricată în totalitate din oțel inoxidabil SUS 304.

2. Ușile de umplere sunt fabricate din SUS316L.

3. Ușile de umplere au o structură rațională cu umplere precisă.

4. Sticlele se mișcă în sus și în jos prin funcția camei prin intermediul ridicatorului, pentru a procesa umplerea cu contact la gura sticlei.

5. Nivelul cilindru este controlat cu sferă flotantă.

6. Umpluitorul este accionat prin inghete din interiorul cadrului mașinii.

7. Roțile de legătură ale spălătoareului, umpluitorului și inchidătorului sunt transportate pe un suport circular al gulerului sticlei.

- Partea de acoperire

- Masa de formare a sticlelor PET

- Sistem de pre-tratare a băuturilor

- Sistem de tratare a apei

- Mașină de etichetare cu mânecă PVC shrink automată

- Mașină de împachetare cu film PE shrink automată