8000BPH комплетна производствена линија за напојување со шишиња за пијалаци со вода

Опис

Јавен, Правилен, Автоматски Апарат за Напојување на Бутилки со Карбонирани Сладоледни Напои

Овој DCGF Мој-Напојување-Затварање 3-в-1 агрегат: Машинерија за Напои се користи за производство на полиестер бутилирани сладоледни напои, содови напои и други карбонирани мешани напои. DCGF Мој-Напојување-Затварање 3-в-1 агрегат: Машинерија за Напои може да заврши сите процеси како што се притискање на бутилките, напојување и затварање, намалува времето на контакт со материјали и спољните додiri, подобрува санитарните услови, производствената капацитет и економската ефикасност.

Суспендираниот структура на конвејер со грбот на бутилката го прави бутилката стабилна во состојба на висока брзина, и го олеснува променувањето на моделот на бутилката. Човек-машински интерфејс со тачковен екран и PLC програмирање го прави производството на висок степен на автоматизација. Сите делови кои имаат директен kontakt со водата се направени од висококвалитетен нержавејќи целик. Главните електрични компоненти се од меѓународно познати компании, како Mitsubishi Schneider, Omron.

| Модел | DCGF12125 | DCGF18186 | DCGF24248 | DCGF323210 | DCGF404012 | DCGF505012 |

| глави за перање, напојување и закапување | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 |

| Производствена капацитет (Б/Х) | 2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 |

| Моторна сила (кВ) | 2.2KW | 2.2KW | 3KW | 5.5КВ | 7,5 KW | 11 kw |

| Тежина (КГ) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 |

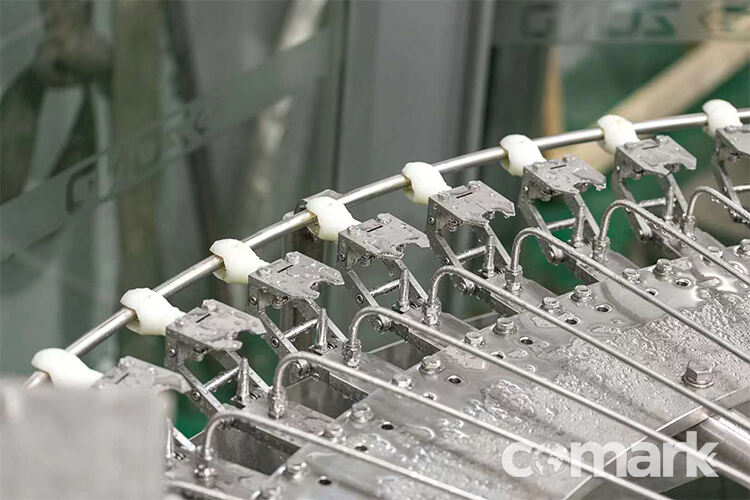

- Дел за перење

1. Ротационниот колесник е структура потпуно засварена од нержавејќа челик.

2. Сите клзачки на подигнувачкиот апарат користат Igus (Германија) противкорозивен безобслужувачки лопастен јачинар.

3. Миялката се движи преку пренос систем позициониран во рамната на машината преку шестерна передова.

4. Машината применува уникален обртлив зачекор за бутили, кој е иновација на нашата компанија. Овој зачекор го држи бутилката во врвната позиција, со што се спречува загадувањето на врвната нишка на бутилката поради резински блокови на традиционалниот зачекор. Изработен од SUS304 нержавејќа челик, овој зачекор е хигиеничен и тргов.

5. Високата ефикасна атомизирачка спреј насадка, инсталирана на бучката за флаши, може да го очисти секој дел од внатрешната страна на флешката и исто така ја штеди промивната вода.

- Дел за полнење

1. Ротационниот колесник е целосно направен од нержавејќа челик SUS 304.

2. Наполнувачките клапи се направени од SUS316L.

3. Наполнувачките клапи имаат рационална конструкција со прецизно наполнување.

4. Флешките се движеат нагоре и надолу во функција на камото преку елеватор, за да се изврши наполнувањето со контакт до устата на флешката.

5. Нивото на цилиндарот се контролира со плутач-топче.

6. Наполнувачката единица се движи преку зупчиња во рамката на машината.

7. Ланц-количките во промивачот, наполнувачот и капачарот се транспортираат во огражда јамка за грбен дел.

- Дел за покривање

- Машина за дување на PET бутилки

- Систем за предобработка на пијалоци

- Систем за трактовка на вода

- Автоматски PVC машин за наметнување на фолии

- Автоматски PE машин за наметнување на фолија